5 Steps to Follow When Setting Up an Engineering & Manufacturing Lab

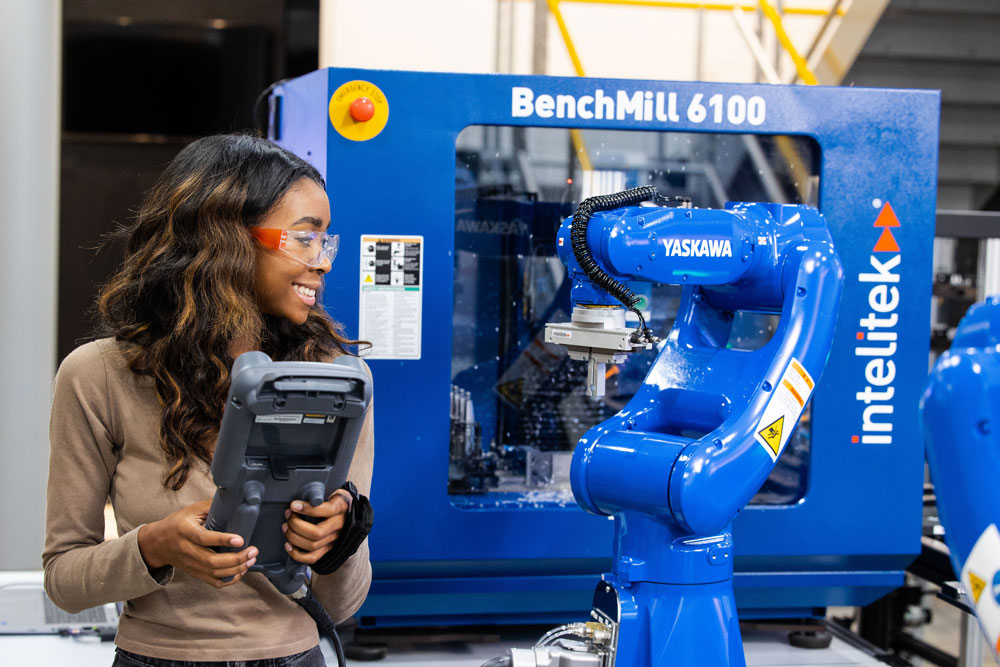

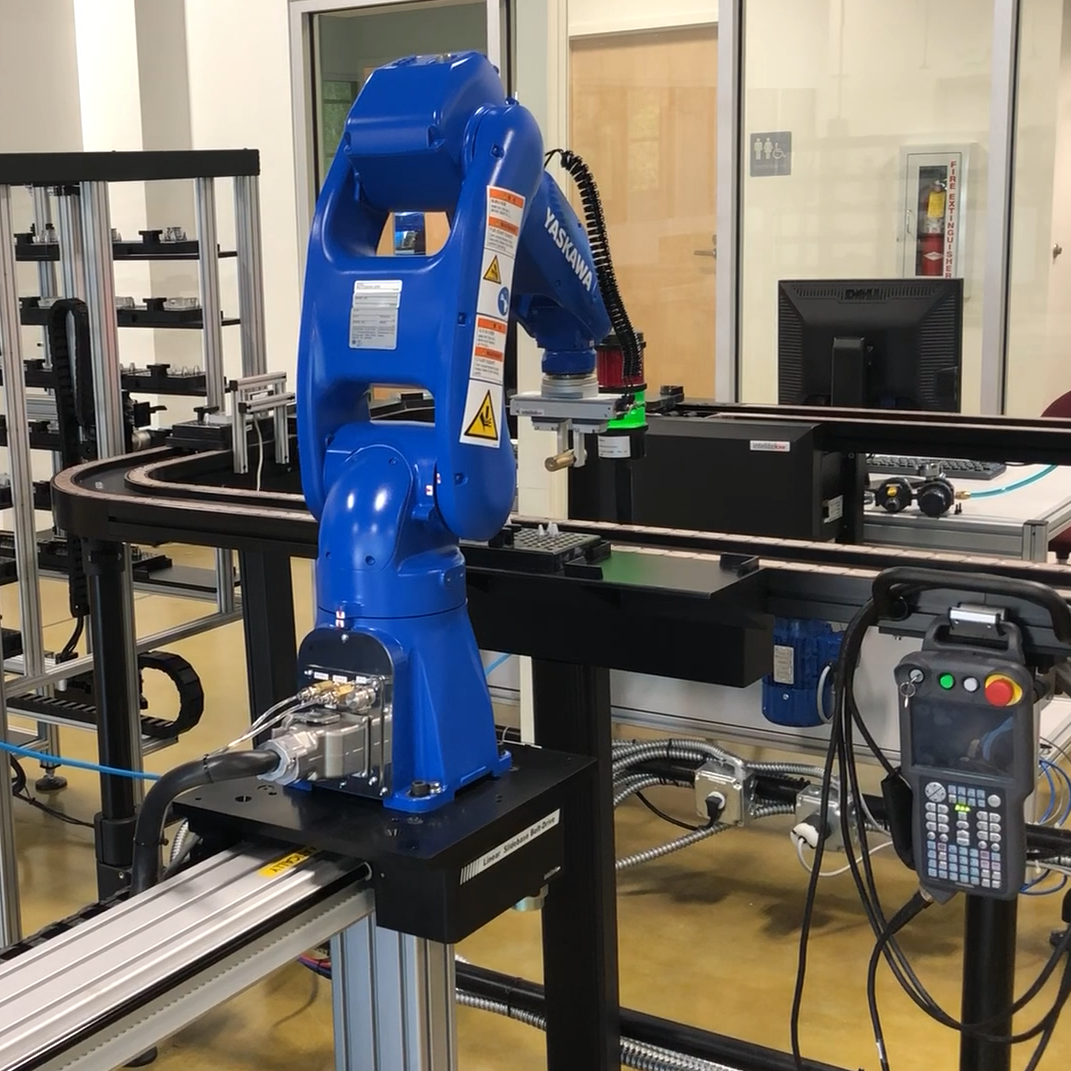

Here’s the pathway that all schools can follow when establishing hands-on learning in engineering, manufacturing, and other STEM-related programs. Before Palo Verde High School in Las Vegas built its manufacturing…